Senior citizens might really like — and use — a 3D printer. That’s the surprising, and money-saving, conclusion of a new study I co-authored: 3D printers can save arthritis patients money by more cheaply manufacturing plastic gadgets that help them do routine tasks like open jars and put on socks.

By 2040, about one-quarter of the U.S. population is expected to have arthritis — a physical ailment making joint movements difficult and painful. In addition to their health care expenses, arthritis patients often have additional needs that do not show up on medical bills and are not covered by insurance. For example, people with arthritic hands can find daily tasks like opening jars — or even eating with a spoon — to be cumbersome and painful. Many companies make and sell adaptive aids like specially shaped spoons and special handles that makes a toothbrush easier to hold. Some patients need dozens of these sorts of items, to help with various daily tasks. But those devices can be expensive — a basic adaptive spoon can cost US$25, vastly more than a standard spoon in any shop.

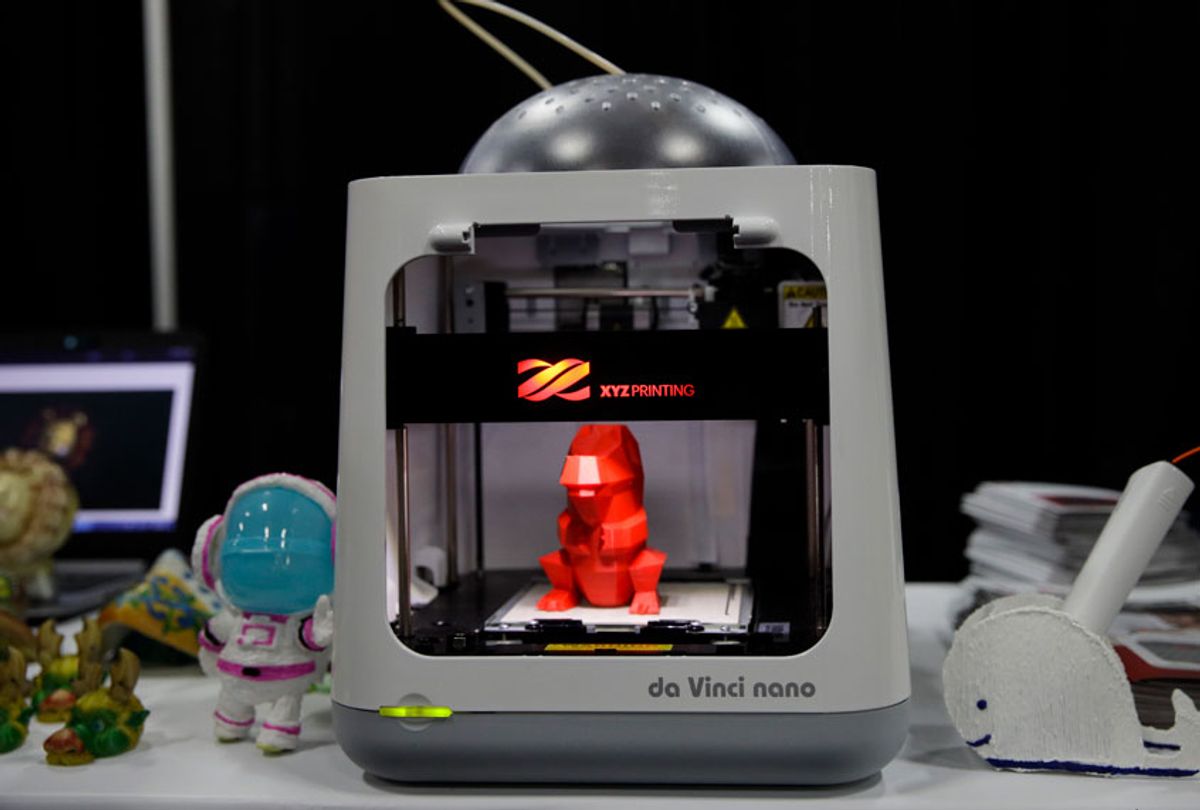

Other assistive items like key holders and pill-splitters can help arthritis patients continue to live independently. Though many of these items are made of cheap plastic, the costs can be prohibitively high for poor people as well as better-off people living on fixed incomes. Research I participated in found that using free online designs and a basic 3D printer to make these assistive aids can save arthritis patients more than 94 percent of the cost of the commercially available products. A typical adaptive aid costs about $25; a 3D printed one costs about a dollar. That generates savings that add up to more than cover the cost of the printer itself.

What would Grandma make?

There are dozens of adaptive aids that can be printed for pennies, helping with tasks like refueling a car, chopping vegetables and using scissors.

Our study technically and economically evaluated 20 fully free open-source designs for adaptive aids designed by Michigan Tech students and made available on Appropedia and MyMiniFactory. This is just a tiny fraction of the 3D printed products available for anyone with access to a 3D printer. People can download not just the designs for free, but also software that lets them adapt, personalize or customize the items for themselves or their loved ones.

We found that we could 3D print all 20 example adaptive aids for $20 – the cost of the plastic filament the 3D printer uses to make items. On the commercial market, the adaptive aids would cost over $20 each. A person, or family, who 3D printed 25 aids would save enough to more than pay for a relatively inexpensive $500 3D printer – and a senior center that 3D printed another 50 could easily recoup the cost of a middle-range commercial desktop 3D printer.

Some people’s insurance or Medicare plan does help pay for adaptive aids. But even then patients usually must pay a portion, with copays around 20 percent. Our analysis found that even this group of patients would save significant amounts of money 3D printing their assistance items at home.

Arthritis attacks the young, too

Arthritis is not just for old people. For example, professional tennis player Caroline Wozniacki was diagnosed with rheumatoid arthritis at age 28, just a few weeks before the 2018 U.S. Open. Like most young people diagnosed with arthritis, she was shocked.

Younger people diagnosed with what is often viewed as an old person’s disease may feel embarrassed and want to limit the number of people who know about their condition. Those patients would no doubt be glad to save the money, but perhaps be even more interested in 3D printing because it would let them customize and build their aid items in the privacy of their own homes.

Consider, for example, the normally private act of clipping your toenails. Some people with arthritis find it difficult to do this with small nail clippers, so they get pedicures that cost in general between $35 and $60. Some might pay $36 to buy a plastic handle that attaches to a standard nail clipper, letting them cut their own nails at home. But a 3D printed handle costs about a dollar — a 97 percent savings.

How can you get 3D printed aids?

Making adaptive aids using a 3D printer is particularly useful because of how easy it is to customize printed items for a person’s hand size or personal aesthetic. The software programs that make and modify designs, and that control 3D printers, are getting easier to use; in any case, many older people are technically adept. In fact, some of the best 3D printable designs for recyclebots were made by a retired engineer.

Of course, not everyone is interested in buying the machinery or learning how to use it. In many communities there are volunteers who are willing to help people with disabilities or medical conditions make what they need. The Makers Making Change nonprofit group even takes requests online. Many community centers and local libraries also offer machinery, software and knowledgeable helpers. Senior centers and medical offices may soon start offering similar services as well, helping people with arthritis help themselves every day.

Joshua M. Pearce, Professor of Materials Science and Engineering, and Electrical and Computer Engineering, Michigan Technological University

This article is republished from The Conversation under a Creative Commons license.

Shares